By integrating a variety of new technologies such as Al, deep learning, big data, etc., create the Intelligent Process Agent with the ability of "thinking, learning and decision-making". Combined with the "cloud-edge-end" product form, the Intelligent Process Agent matches the optimal process solution for customers, and provides decision support, simulation, and prediction functions.

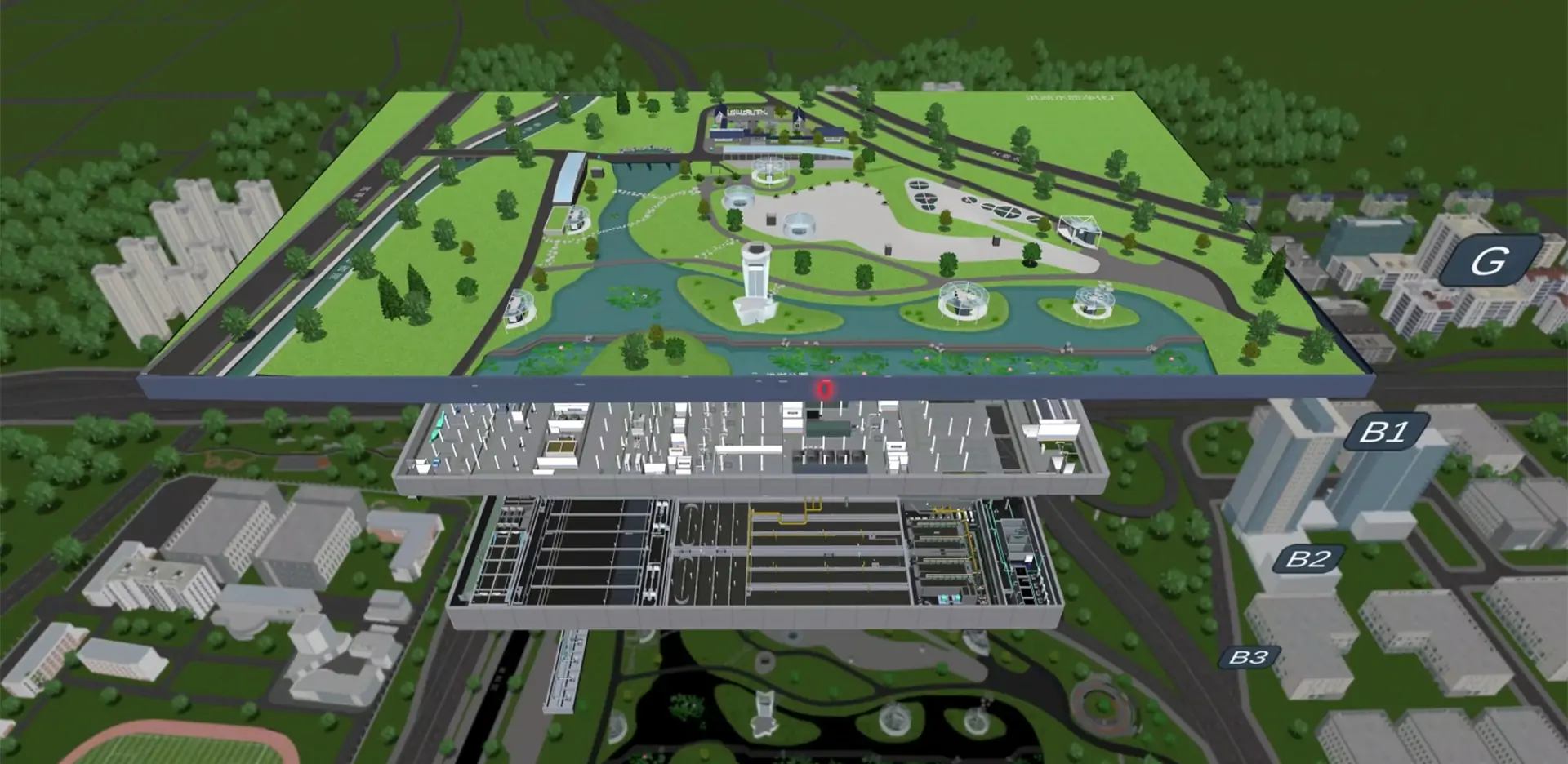

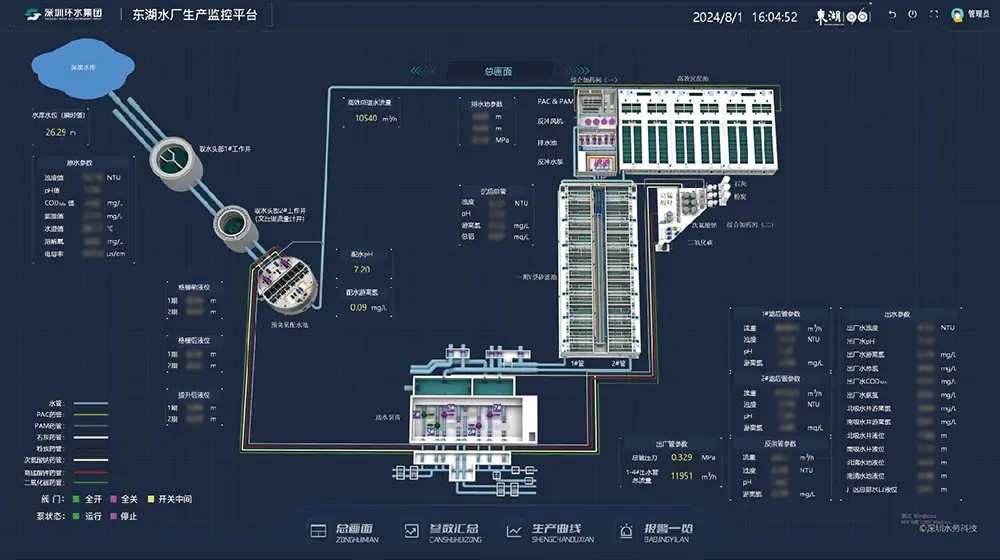

Smart Water Treatment Plant Solution (SWTP)

● Intelligent Dosing System

1. PAC applied in 14 water plants, Sodium Hypochlorite applied in 5 water plants and chemicals such as lime and sodium hydroxide have been applied in 1 and 2 water plants respectively.

2. 'Feed forward + Model + Feedback' Mode, Precisely adjust the dosage of chemicals added. Fast deployment and installation, commissioning within just 1 month.

3. Strong impact-resistance capability, has already cope with water quality changes 192 times.

4. Reduction of manual intervention by up to 95%-99%.

5. Chemical consumption optimization up to 12%-28%, 20% reduction of turbidity fluctuation in post-settling water.

● Water Equipment Prediction Product and Health Management Service

1. Applied in 6 plants in Shenzhen.

2. Malfunction can be pre-detected 15 days before.

3. 24x7 continuous monitoring of equipment performance.

● Intelligent Water Balance System

Supply based on demand, with dynamic adjustments to ensure equilibrium between production and supply.

● Pump Optimization

Optimize the control of pump start-stop cycles and valve operations to reduce energy consumption.

● Intelligent process simulation

Combined with simulation model, guide production and improve control level.

Smart Wastewater Treatment Plant Solution

● Intelligent aeration control

1. Watech-intelligent Aeration System

2. Applied in 5 plants in Shenzhen.

3. Electricity Saving: Up to 15%

4. Precise control model based on constant DO + ammonia feedback to achieve dynamic balance between supply and demand of aeration.

5. Customized development and deployment, costs are manageable.

● Chemical phosphorus removal control

The dosage of PAC is precisely calculated based on the total phosphorus or orthophosphate content in the water to enable automatic dosing and minimize chemical consumption.

● Carbon source addition control

The carbon source dosage is automatically calculated based on the nitrate nitrogen concentration at the end of the aerobic zone in the biological reactor, as well as other relevant water quality parameters.