- Home

-

Solution

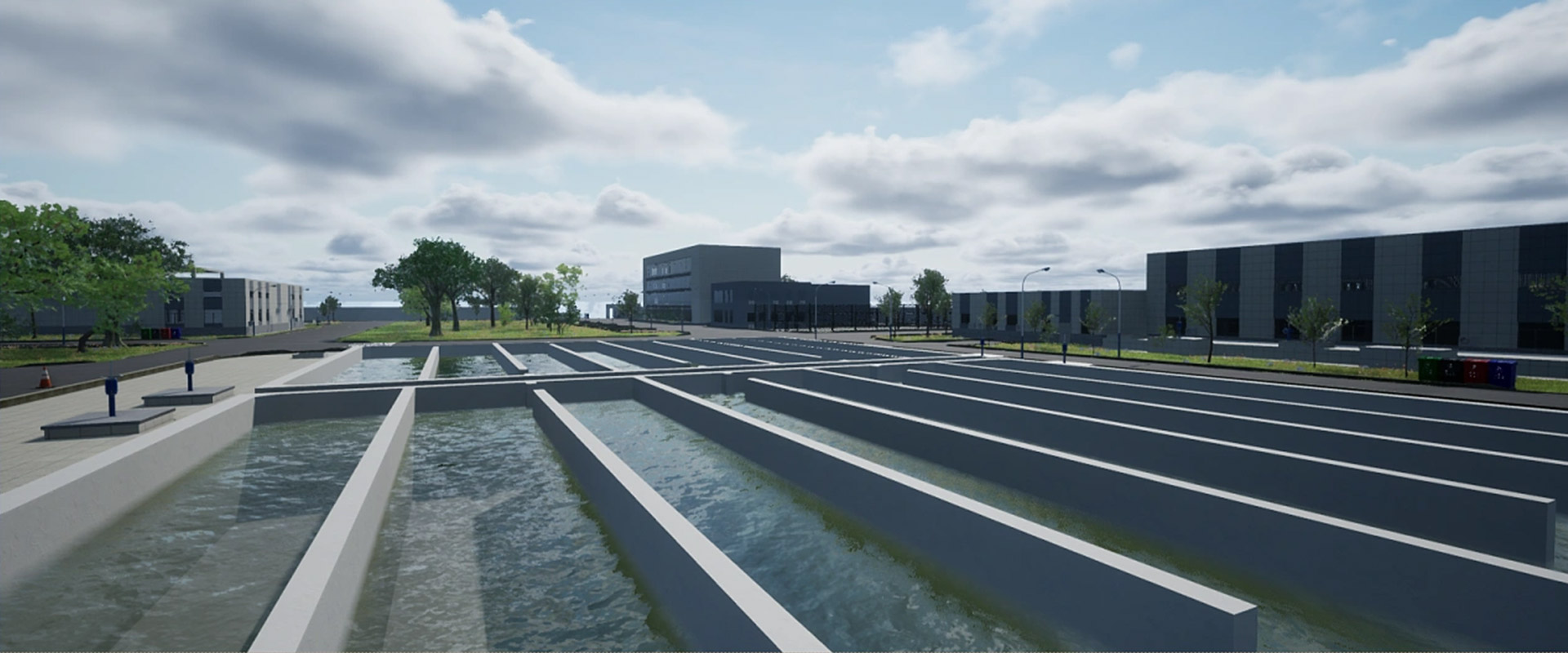

Smart Water-Related Affairs Solution

-

WATECH Products

- Integration & Services

- Typical Case

- News

- About us